Project Scope

Ingenia was engaged by a major industrial client to address significant vibration issues in a pumping line under a design and construction support arrangement. The existing system induced pulse loads into the pipework, leading to severe vibration and movement of supporting platforms, which caused fatigue in the pipe mounts and support frames. Ingenia’s scope included conducting a comprehensive pipe flexibility analysis of the existing system and designing support structures to reduce vibration and ensure stability.

Challenges

Ingenia began the project by thoroughly assessing the pumping line’s performance, system geometry, and the loads impacting the pipeline. We utilised a 3D point cloud scan (Terrestrial Scan) of the area to accurately capture the geometry, which differed from existing documentation, and developed an As-Built model of the pipework.

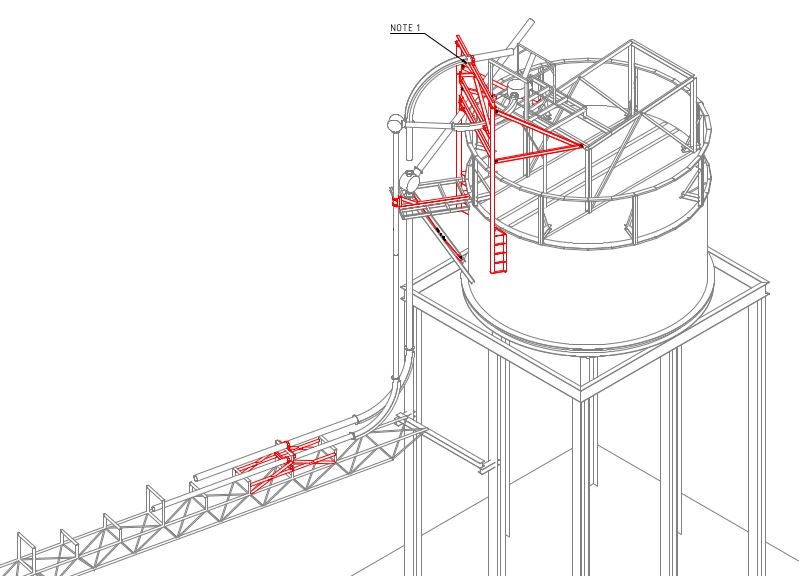

During the pipe flexibility assessment, Ingenia identified that the initial installation had not accounted for the loads introduced by a 45-degree bend. Ingenia designed new supports to reinforce this section and additional areas, aiming to minimise displacement through detailed analysis. This process highlighted the need for new support structures at several locations, as shown in the accompanying images.

After finalising the design, the team transformed the results from the pipe flexibility analysis into a 3D CAD model and detailed fabrication drawings. These drawings were then provided to Smart Fabrication, who manufactured the supports ready for installation.

Conclusion

Ingenia’s project managers efficiently coordinated the onsite installation of the fabricated supports during a scheduled site shutdown, ensuring minimal disruption to ongoing operations. Post-installation, a site lead commented positively on the improvements, noting that the vibrations had significantly decreased and that they felt secure walking on the service platforms once again.

Our Services Discover how our engineering services can support your next project!